Print-on-Demand Fulfillment: Maximizing Efficiency & ROI

The personalized products market has experienced exponential growth, driving significant expansion in the print-on-demand (POD) business model. This approach has revolutionized e-commerce by enabling on-demand product customization, effectively eliminating inventory holding requirements and minimizing financial risk exposure.

Managing internal POD operations presents substantial operational challenges, though. From capital-intensive equipment investments to maintaining consistent quality at scale, many enterprises discover that outsourcing POD fulfillment to specialized partners represents a more strategic allocation of resources.

Unlike traditional fulfillment operations where products arrive ready for distribution, POD fulfillment requires seamless integration between design systems, production workflows, and shipping processes; rigorous quality assurance protocols for each customized item; and compressed production timeframes from order receipt to shipment.

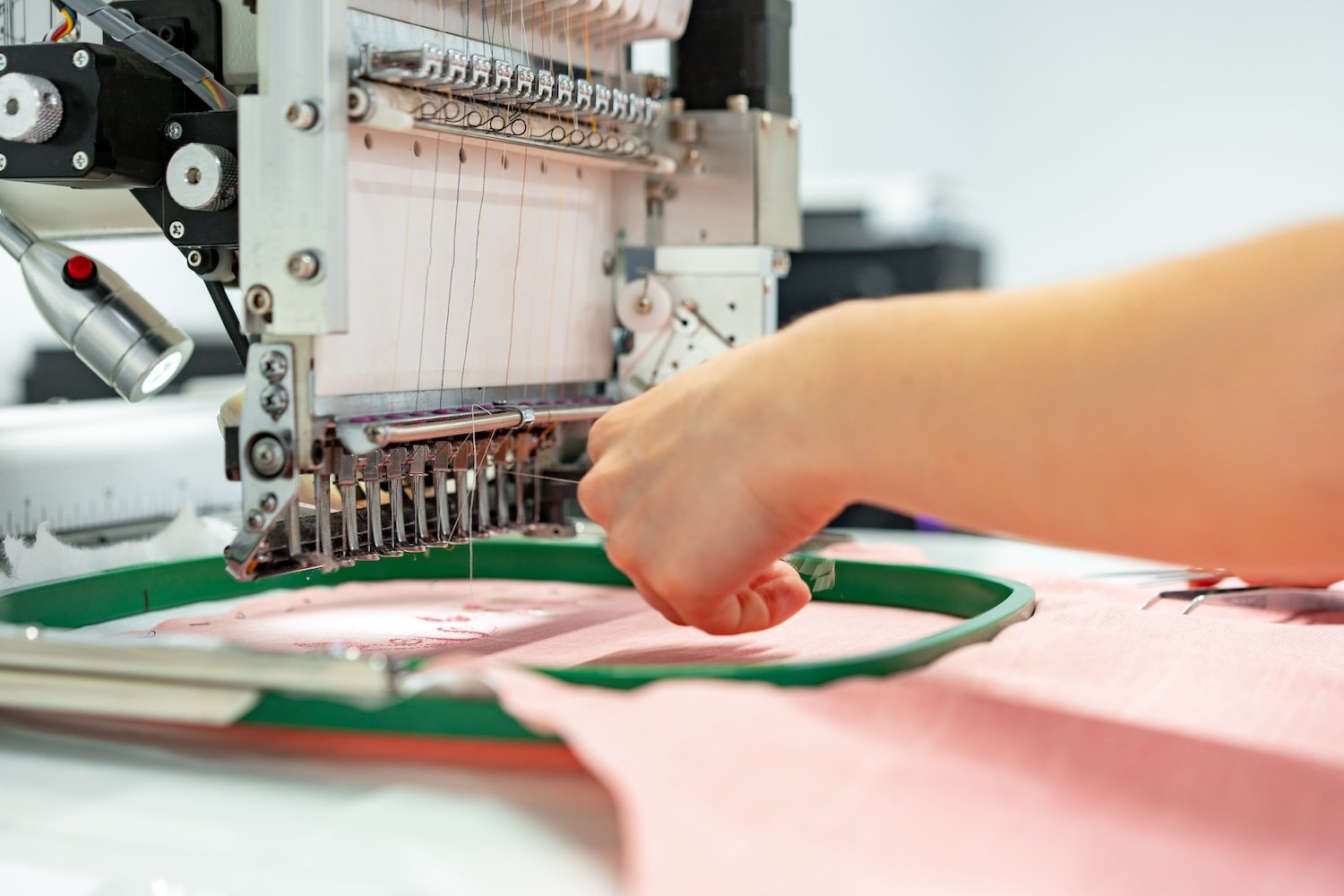

POD operations depend on advanced production equipment and systems that require substantial capital expenditure, demand specialized maintenance protocols, and necessitate continuous technology upgrades to maintain competitive capabilities.

Seasonal promotions, product launches, and marketing campaigns generate significant demand volatility requiring flexible production capacity, scalable staffing resources, and optimized workflows to prevent fulfillment delays.

Outsourcing POD fulfillment operations enables elimination of significant equipment capital expenditures, reduction of physical infrastructure requirements, and transformation of fixed costs into variable expenses aligned with business performance.

Specialized POD partners provide state-of-the-art printing technologies for diverse materials and applications, automated systems minimizing production errors while maximizing throughput, and established quality control processes ensuring consistent output.

Outsourcing operational complexities allows leadership to reallocate resources toward marketing initiatives and product development, explore market expansion opportunities and product category diversification, and focus on customer experience optimization and brand development.

When evaluating potential POD fulfillment partners, assess their production quality standards including print resolution capabilities across various substrate materials, color consistency and accuracy measures, and multi-stage quality inspection protocols.

Optimal partners offer integration technology infrastructure providing automated order synchronization with e-commerce platforms, real-time production status visibility, and proactive issue notification protocols.

Time-sensitivity significantly impacts e-commerce success, so verify clearly defined order processing SLAs, demonstrated capacity to maintain performance standards during volume fluctuations, and documented on-time delivery performance history.

Partner flexibility directly impacts your customer offering through product and material range availability, custom packaging options, and marketing material inclusion capabilities.

At Dimona Fulfillment Solutions, we've developed a specialized approach to print-on-demand fulfillment that integrates advanced technology, optimized processes, and industry expertise.

Our infrastructure incorporates state-of-the-art printing technologies for diverse applications—from apparel (t-shirts, hoodies) to accessories—with rigorous quality control protocols at every production stage.

Our proprietary technology integration enables comprehensive order visibility from receipt through delivery, providing real-time status updates and complete operational transparency. Additionally, our scalable production capacity ensures consistent performance during high-volume periods.

Implementing a specialized POD fulfillment solution delivers measurable improvements across key performance indicators: 24-48 hour order processing for domestic shipments, 99.9% order accuracy rates through automated quality control, significant reduction in capital expenditure requirements, and enhanced ability to scale during promotional periods.

Print-on-demand offers transformative opportunities for enterprises and established brands by eliminating traditional inventory barriers and capital requirements. However, maximizing this model's potential requires specialized fulfillment expertise that understands the unique challenges of on-demand production.

By partnering with a POD fulfillment specialist like Dimona, organizations not only optimize current operations but establish the foundation for sustainable, scalable growth. Our technology-driven approach transforms print-on-demand logistics from an operational challenge into a strategic advantage.

Want to see how our specialized POD solutions can enhance your business? Contact our print-on-demand consultants today to explore how Dimona's enterprise fulfillment solutions can optimize your POD operations. Our team will conduct a comprehensive analysis of your current workflow and demonstrate how our tailored approach can enhance production quality, reduce operational costs, and improve customer satisfaction.