2025 Print-on-Demand Trends: AI, Sustainability, and Hyper-Personalization

The print-on-demand (POD) industry continues to evolve rapidly, with 2025 marking a pivotal year as three powerful trends converge: artificial intelligence integration, sustainable production practices, and hyper-personalized customer experiences. These developments are transforming not just how products are created but the fundamental business models and competitive advantages within the industry.

At Dimona, we're strategically positioned at the forefront of these industry shifts with advanced POD capabilities and fulfillment centers optimized for nationwide distribution.

AI Integration: Transforming POD Production and Design

Artificial intelligence is revolutionizing multiple aspects of print-on-demand:

AI-Driven Design Generation

Creative development is being transformed through:

- Generative Design Platforms: AI systems creating unique artwork from text prompts

- Style Transfer Technology: Algorithms applying artistic styles to basic concepts

- Design Optimization: Automatic refinement for specific products and printing methods

- Customization Engines: Systems generating personalized designs at scale

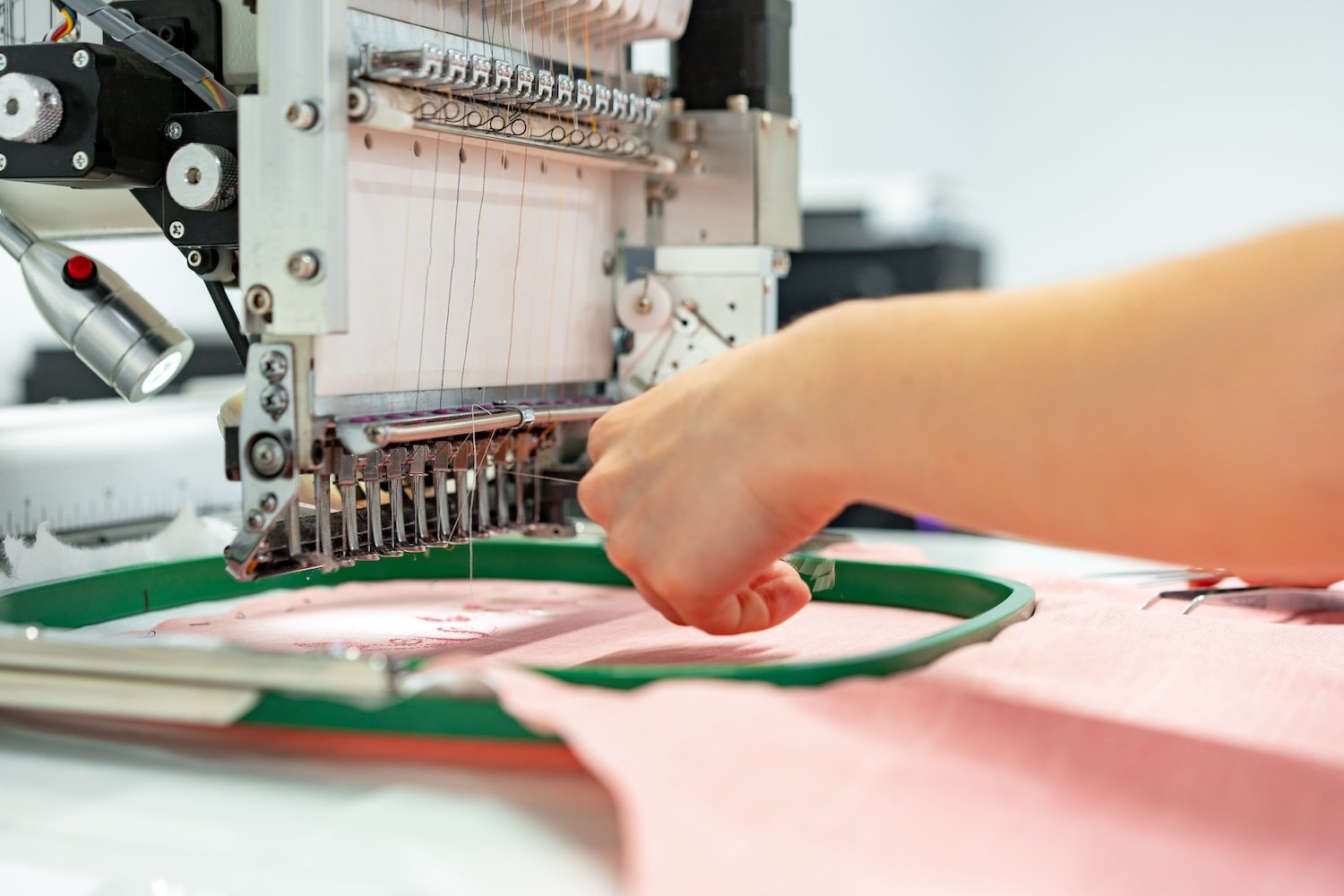

Advanced printing technologies like direct-to-garment and embroidery now support these AI-generated designs, ensuring high-quality production regardless of design complexity.

Predictive Production and Inventory Management

AI is revolutionizing operational efficiency:

- Demand Forecasting: Algorithms predicting product popularity before production

- Smart Inventory: AI systems optimizing blank stock levels across facilities

- Production Scheduling: Automated workflow optimization based on priorities and capacity

- Predictive Quality Control: Identifying potential issues before they occur

These capabilities are transforming how fulfillment centers manage inventory and production, enabling multi-stage inspection processes that ensure near-perfect order accuracy.

Sustainability: From Optional to Essential

Environmental responsibility has evolved from marketing advantage to business imperative:

Eco-Friendly Materials and Processes

Sustainable practices are advancing across production phases:

- Water-Based Inks: Lower environmental impact with reduced chemical content

- Organic and Recycled Fabrics: Expanding availability of sustainable base products

- Energy-Efficient Equipment: Reduced consumption through optimized production

- Waste Reduction Systems: Minimizing material waste throughout workflows

Climate-controlled warehousing facilities support these initiatives while maintaining product quality throughout the supply chain.

Circular Production Models

Beyond materials, business models are evolving:

- Zero-Inventory Production: Eliminating waste from unsold stock

- Recyclable Packaging: Reducing landfill impact from shipping materials

- End-of-Life Programs: Creating pathways for product recycling

- Carbon-Neutral Operations: Offsetting remaining emissions through verified programs

Hyper-Personalization: Beyond Basic Customization

The personalization revolution extends well beyond adding names to templates:

Dynamic Content Personalization

Next-generation customization includes:

- Variable Data Printing: Unique elements on every single item

- Contextual Design Adaptation: Products that reflect customer location, interests, or history

- Behavioral Design Targeting: Suggested customizations based on past preferences

- Occasion-Specific Personalization: Designs tailored to specific events or milestones

The most forward-thinking production facilities now offer high-volume capabilities with no minimum order requirements, making these personalization approaches economically viable even for smaller campaigns or niche audiences.

Interactive Design Experiences

Customer involvement has become crucial:

- Augmented Reality Visualization: Real-time product previews before production

- Collaborative Design Platforms: Shared creative environments with designers

- AI Design Assistants: Guided personalization through intelligent interfaces

- Social Design Sharing: Community input on customization choices

API-driven automation enables seamless connectivity with these interactive e-commerce platforms, ensuring design integrity is maintained from visualization to final production.

The Convergence Advantage: Where These Trends Intersect

The most powerful opportunities emerge where these trends overlap:

AI-Powered Sustainable Production

The combination of AI and sustainability creates unique benefits:

- Material Optimization: Systems that minimize waste through efficient design layouts

- Energy Usage Prediction: Intelligent scheduling during lower-consumption periods

- Automated Quality Control: Multi-stage inspection processes reducing waste from production errors

- Resource-Efficient Routing: Strategically located facilities optimizing production distribution

Personalization with Reduced Environmental Impact

Businesses can effectively combine customization and sustainability:

- Right-Sized Production: Creating exactly what customers want with minimal waste

- Digital Sampling: Eliminating physical samples through visualization technology

- Localized Production: Reducing shipping distances through distributed manufacturing networks

- Customer-Driven Sustainability: Involving consumers in eco-friendly choices

Implementation Strategies for Forward-Thinking Businesses

Practical approaches to leveraging these trends include:

Phased Technology Adoption

A systematic implementation approach:

- Assessment Phase: Evaluate current capabilities against emerging trends

- Strategic Planning: Prioritize implementations based on specific business needs

- Integration Setup: Connect with API-driven systems for seamless e-commerce connectivity

- Iterative Scaling: Leverage infrastructure designed to handle seasonal spikes and rapid growth

Strategic Partnership Approach

Leveraging specialist expertise accelerates implementation:

- Technology Integration: Real-time inventory sync with existing systems

- Fulfillment Excellence: Rapid order processing improves customer satisfaction

- Sustainability Implementation: Access to eco-friendly packaging and carbon-neutral shipping options

- Global Distribution: Expertise in customs clearance and cross-border logistics

Preparing for the Future of Print-on-Demand

As AI integration, sustainability practices, and hyper-personalization continue to reshape the print-on-demand landscape in 2025, businesses must evolve their strategies to remain competitive. By partnering with specialists like Dimonas, companies can quickly implement these trends without substantial infrastructure investments or operational overhauls.

The future of print-on-demand belongs to businesses that effectively harness these trends to deliver products that are simultaneously more personalized, more sustainable, and more efficiently produced than ever before.

Ready to implement these emerging trends in your print-on-demand business? Contact Dimona to discuss how our advanced capabilities can help you stay ahead of the curve.